1. Innovation in D-SUB Shell Design

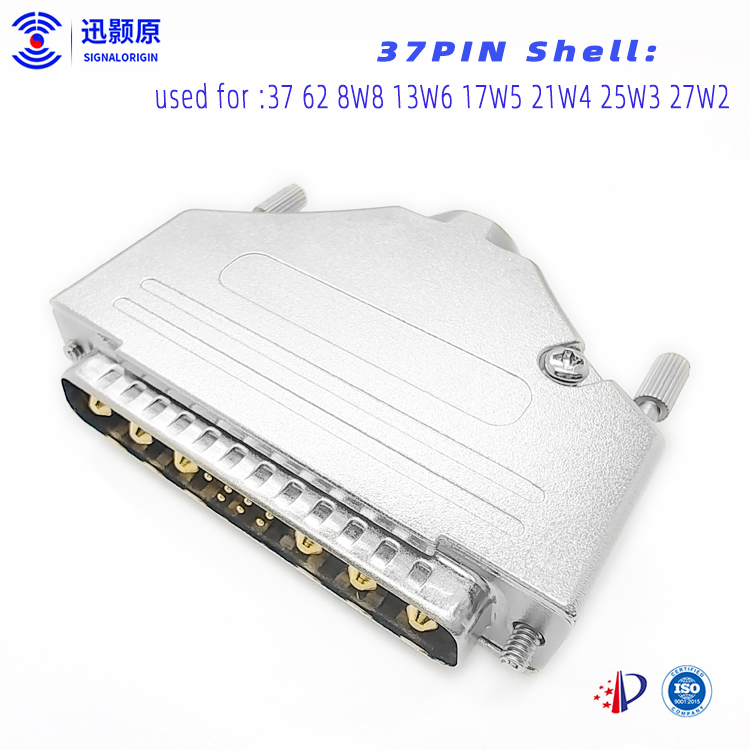

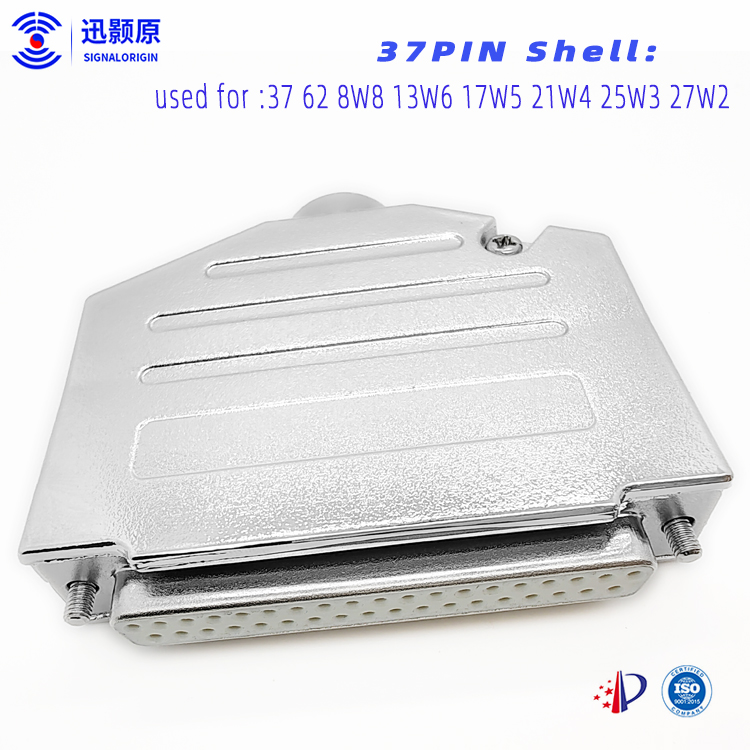

The D-SUB shell has long been a fundamental component in reliable electrical connections. With the growing demand for compact, durable, and high-performance connectors, our company introduces a new generation of D-SUB shells engineered for superior precision design and structural integrity. By adopting advanced production techniques and strict quality control, each connector housing ensures stable performance even under challenging environmental conditions. Our engineers have focused on optimizing the mechanical fit and improving metal shielding for better signal integrity.

2. Enhanced Durability and Metal Shielding

Durability remains the core value of our D-SUB shell products. Each housing is built with high-grade materials that resist corrosion, vibration, and mechanical stress. The enhanced metal shielding structure effectively reduces electromagnetic interference (EMI), ensuring reliable data transmission. This improvement not only strengthens the product’s resistance to external noise but also meets the growing market requirement for long-term performance. The connector housing has been tested to perform under extreme industrial environments, demonstrating remarkable durability and consistency.

3. Precision Engineering for Modern Applications

In today’s high-speed and compact device landscape, precision design defines the success of connection solutions. Our latest D-SUB shell models are designed with meticulous attention to detail, offering perfect alignment between pins and sockets. This design innovation simplifies assembly and enhances contact stability. By integrating advanced connector housing geometry, we achieve an optimal balance between performance and ease of use. The application range now extends across industries such as automation, aerospace, and data communication.

4. Sustainability and Customization

Beyond performance, sustainability is now a key factor in production. Our D-SUB shell manufacturing process emphasizes eco-friendly materials and recyclable metals. We also provide customized connector housing options to meet diverse customer requirements. Whether it’s precision design for medical devices or reinforced metal shielding for industrial automation, our tailored solutions deliver both environmental responsibility and product excellence.

5. Future Vision and Global Standards

As the global demand for advanced connection systems continues to expand, our company remains committed to innovation in D-SUB shell technology. All products are manufactured under international quality standards, ensuring compatibility with various connector housing systems. Moving forward, we will continue to enhance durability, improve metal shielding efficiency, and refine precision design to meet evolving market needs. Our vision is to become a trusted partner for global industries that value quality, reliability, and innovation in every connection.